© 2026 Truss Machinery Connections, Inc.

Phone: 800-580-6430

Fax: 800-580-6424

•

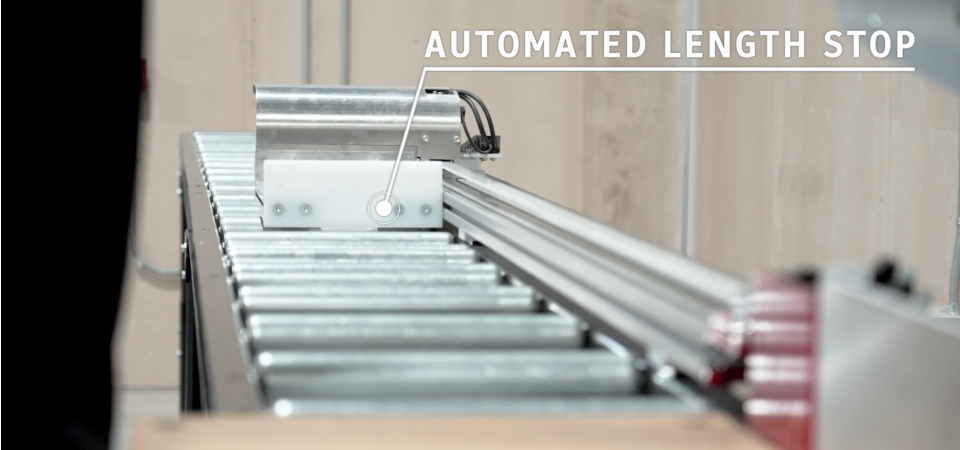

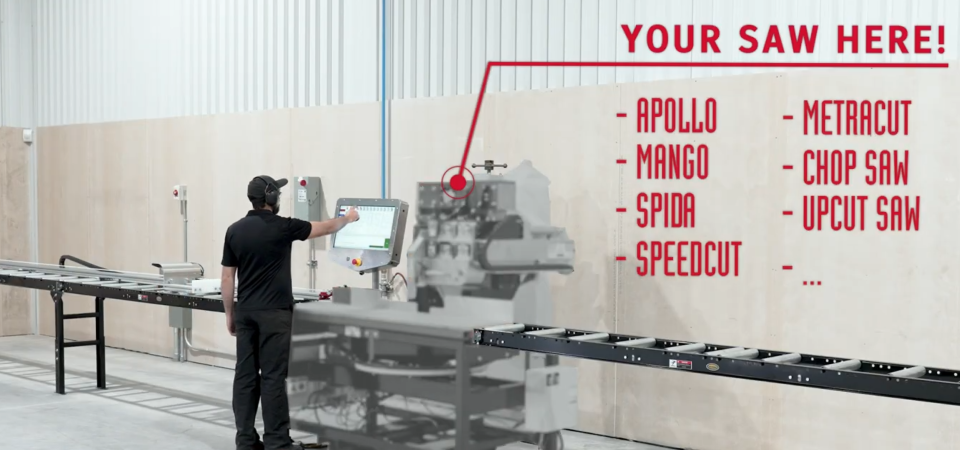

Automates length and angle cuts or length only

•

Fits on your existing saw frame and conveyor

system:

o

asiRS

o

Apollo

o

Spida

o

SpeedCut

o

MetraCut

o

Radial saw

o

Upcut saws

•

Steel reinforced polyurethane positioning belt

ensures accuracy

•

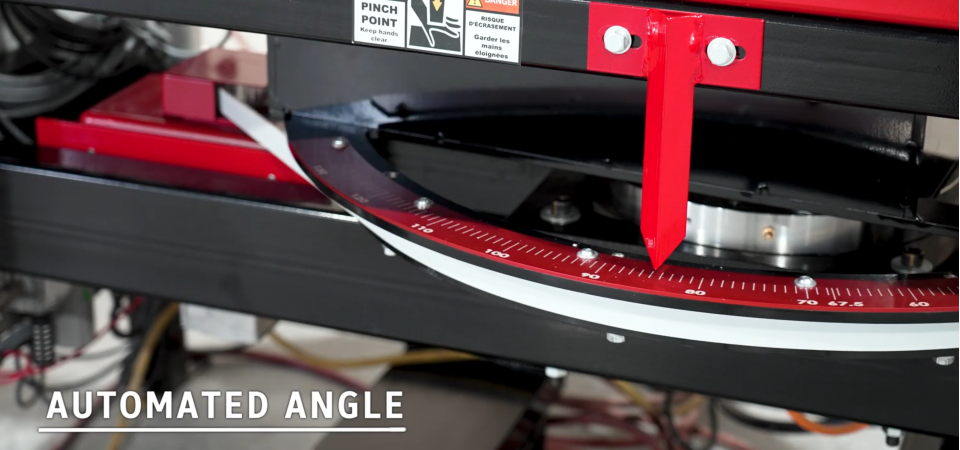

Up to 15°/sec. Angulation

•

Angles adjust from 7° to 90° (frame depending)

> 90° angles done flipping the component

•

Length adjust from 0in to 23ft (frame depending)

•

Can be connected to your network to upload the

cutting lists directly to the computer

•

Saw files read: EHX, TRS, Sapphire XML, EZY,

CYB, WCD, ASI, BTL, BTLx

•

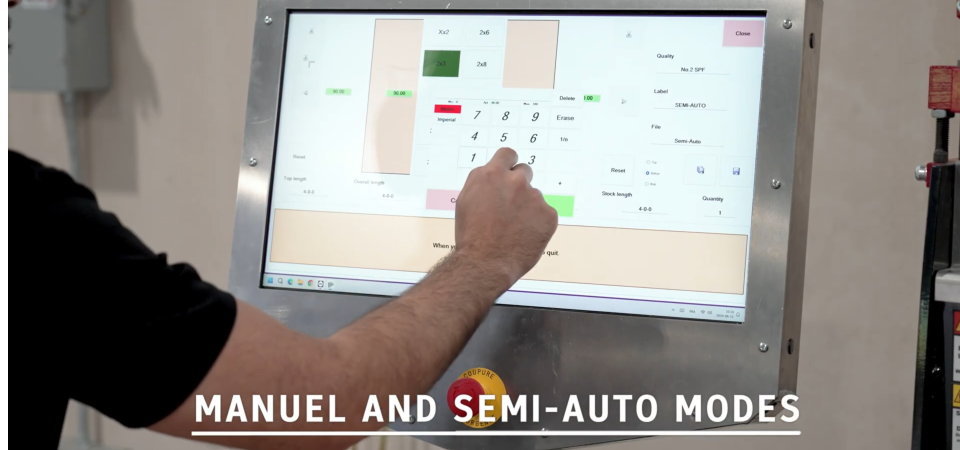

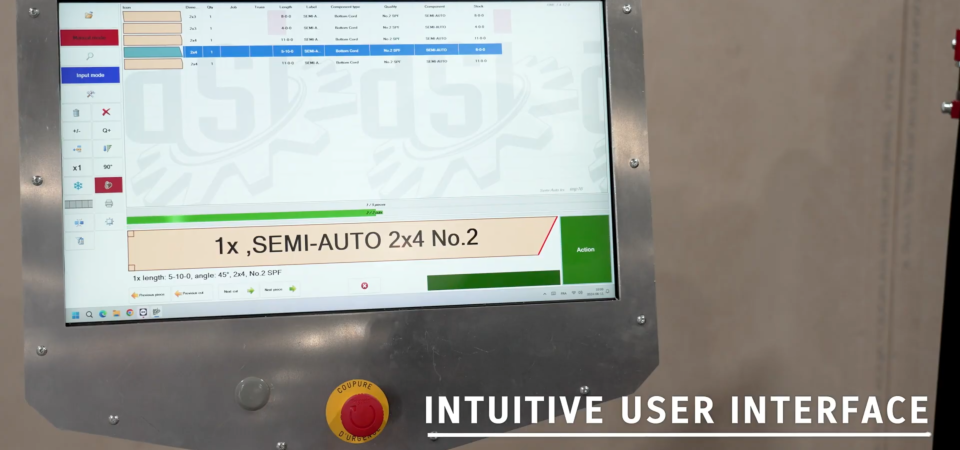

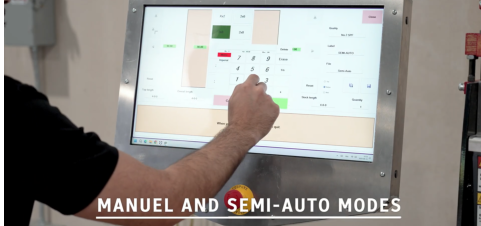

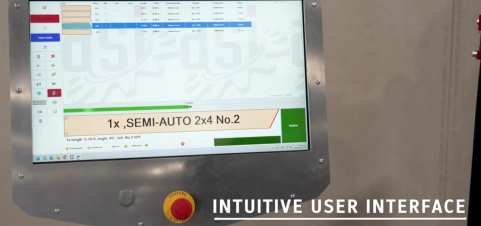

Intuitive multilingual English, French and Spanish

HMI

•

Length and/or angle automation system

•

Up to two (2) high resolution, high speed & high

torque servo motors for accurate positioning with

integrated ILA2 series Schneider-Electric drives.

•

24in Lenovo touchscreen with BasiC software and

ultraintuitive human machine interface.

•

Easy axis by axis calibration.

•

Step by step mode for:

o

Diagnostics

o

Maintenance

o

Cleaning

•

Machine configuration backup system for seamless

recovery/restart

•

Real-time statistics compilation and error tracking,

accessible via our customer portal

•

cULus approved control panel

•

Lifetime access to software updates

•

BasiC L automation for Length Only

o

Plate marker

o

Support table for your saw

•

BasiC AL automation for Angle and Length

o

Trusses + plates

•

Printing System for marking wall plates

o

3 or 4 pens options

•

Customizable length up to 40 ft

•

Lot of roller conveyors and supporting stands

•

Component cart

•

Infeed/Outfeed freestanding track rollers

•

Lot of critical spare parts

•

Periodic maintenance program

© 2026Truss Machinery Connections, Inc.

Phone: 800-580-6430

Fax: 800-580-6424

•

Automates length and angle cuts or length only

•

Fits on your existing saw frame and conveyor

system:

o

asiRS

o

Apollo

o

Spida

o

SpeedCut

o

MetraCut

o

Radial saw

o

Upcut saws

•

Steel reinforced polyurethane positioning belt

ensures accuracy

•

Up to 15°/sec. Angulation

•

Angles adjust from 7° to 90° (frame depending)

> 90° angles done flipping the component

•

Length adjust from 0in to 23ft (frame depending)

•

Can be connected to your network to upload the

cutting lists directly to the computer

•

Saw files read: EHX, TRS, Sapphire XML, EZY,

CYB, WCD, ASI, BTL, BTLx

•

Intuitive multilingual English, French and Spanish

HMI

•

Length and/or angle automation system

•

Up to two (2) high resolution, high speed & high

torque servo motors for accurate positioning with

integrated ILA2 series Schneider-Electric drives.

•

24in Lenovo touchscreen with BasiC software

and ultraintuitive human machine interface.

•

Easy axis by axis calibration.

•

Step by step mode for:

o

Diagnostics

o

Maintenance

o

Cleaning

•

Machine configuration backup system for

seamless recovery/restart

•

Real-time statistics compilation and error

tracking, accessible via our customer portal

•

cULus approved control panel

•

Lifetime access to software updates

Truss machinery Connections, Inc

•

BasiC L automation for Length Only

o

Plate marker

o

Support table for your saw

•

BasiC AL automation for Angle and Length

o

Trusses + plates

•

Printing System for marking wall plates

o

3 or 4 pens options

•

Customizable length up to 40 ft

•

Lot of roller conveyors and supporting stands

•

Component cart

•

Infeed/Outfeed freestanding track rollers

•

Lot of critical spare parts

•

Periodic maintenance program